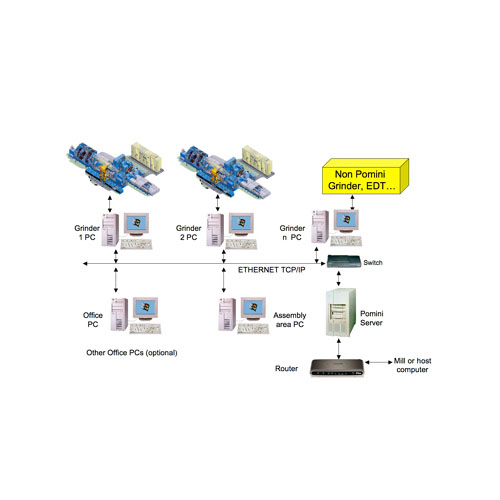

Modern roll shops have a high degree of automation, allowing a single operator to supervise several grinding machines, as well as storing a lot of grinding information in centralized databases for each roll in the roll shop. This information is normally kept in database servers and is useful by itself, but it can be much more useful if it is organized well and correlated to mill production data. That is the purpose of a roll shop management system (RSMS). Such systems manage a lot of information about rolls, but also about chocks, bearings and grinding wheels, correlating grinding data to mill production data, to permit evaluation of the performance of rolls, chocks, bearings and wheels in the grinder and/or in the mill. Roll shop management systems also provide an inventory of all the rolls, chocks, bearings and wheels in the roll shop, and for each indicate the history and the current status. For chocks and bearings, such systems will also indicate when maintenance needs to be performed. The goal of an RSMS is therefore to move from the mere automation of a roll grinding machine to supporting the decisions made daily in the roll shop. The Pomini Roll Shop Management System provides a complete solution for supporting the roll shop manager’s decisions.