Strip tension measurement in applications such as continuous annealing, galvanizing and the like are a real technological challenge which calls for a great deal of special expertise on the part of the engineer of strip tension measuring systems.

The excessive temperature differences arising between start-up and operation of the oven or furnace do not or very rarely allow measurements to be conducted by systems employing traditional strip tension measuring techniques.

The underlying objective of measuring technological efforts is to eliminate to the extent possible all momentums that may have detrimental effects on the measurement itself.

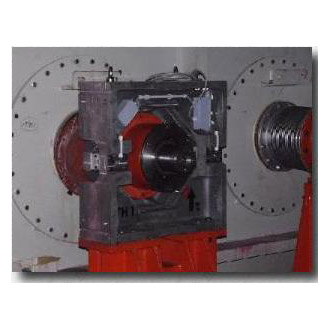

For applications of this nature we offer our customers a specially designed strip tension measuring frame that enables momentum-free strip tension measurements to be performed.

Features:

- Momentum-free measurement of strip tension in hot zones of continuous annealing plants, galvanizing equipment etc.

- Coverage of horizontal, vertical and biaxial measuring directions

- Protection against HF interference through integrated pre-amplifiers

- Special measuring frames delivered to the site in ready-to-mount condition

- The unit is easily mounted due to compact, low-weight aluminum frame castings

- Simple handling when the Plant Operator has to change the rolls

- Measuring properties remain constant over very long periods of time

- Many hundreds of these systems are in use worldwide

| Nominal load |

: |

bis 40 kN |

| |

|

8-times overload without detrimental effects |

| Supply voltage |

: |

35 VDC |

| Combined error |

: |

0,3 % |

| Hysteresis and linearity |

: |

0,25 % of full scale |

| Reproducibility |

: |

0,1 % of full scale |

| Response to temperature changes /10K |

: |

0,1 % of full scale |

| Compensated temperature range |

: |

+20°C…+80°C |

| Admissible temperature range (with special cable) |

: |

0°C…+125°C |